The Greatest Guide To Powder Coating In Santa Clarita

Wiki Article

The Greatest Guide To Powder Coating In Santa Clarita

Table of ContentsWhat Does Santa Clarita Powder Coating Mean?Not known Factual Statements About Powder Coating In Santa Clarita Powder Coating In Santa Clarita for BeginnersThe Santa Clarita Powder Coating StatementsRumored Buzz on Powder Coat Santa ClaritaWhat Does Powder Coating Santa Clarita Mean?Our Powder Coat Santa Clarita PDFsThe Single Strategy To Use For Santa Clarita Powder Coating

Unlike several various other covering processes, powder finishing is a dry finishing process, which implies that it is solid when applied to the base material. A lot of layers are used as fluids for adhesion objectives. Powder finishing is applied dry since it has the ability to use electrostatics to stick the layer product to the substrate being coated.View Powder Coating Plus, Inc. Santa Clarita in a full screen map

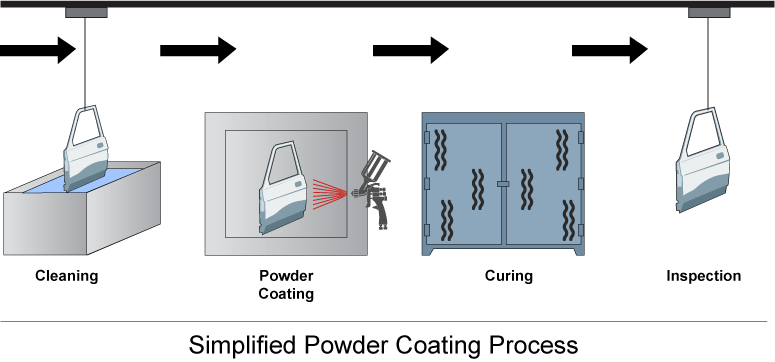

How is a Powder Layer Applied? Perhaps the most usual approach of using a powder finish is via the usage of a powder coating spray gun. This method pushes the powder finish material at the substrate being covered, while additionally offering the fragments an electrostatic fee. The substratum being coated is based which attracts the electrically charged particles, assisting to form a bond.

Rumored Buzz on Santa Clarita Powder Coating Shop

This supplies warm which creates the powder to bond with each other and stick to the base product without the demand for an electrical charge. UV light may additionally be used in addition to, or instead of, healing ovens. santa clarita powder coating. One more approach of applying a powder layer is via the usage of a fluidized bed.After being submerged, the layered component is possibly based on post-curing, depending on the sort of base as well as layer product. powder coating santa clarita. What Are The Sorts Of Powder Layer? While there are numerous different selections of powder finishing that can be utilized relying on task problems and needs, powder layer products can usually be categorized as either as well as.

Powder Coat Santa Clarita Things To Know Before You Get This

Once cured, thermosets are less impacted by temperature, that makes them excellent for greater temperature level applications. They can likewise be a more economical finishing method than some kinds of thermoplastics. What Metals Can Be Powder Coated? Basically all metal kinds can be powder covered. This is because they are able to hold an electrostatic charge to have powder covering material abided by them.

Not known Incorrect Statements About Powder Coating In Santa Clarita

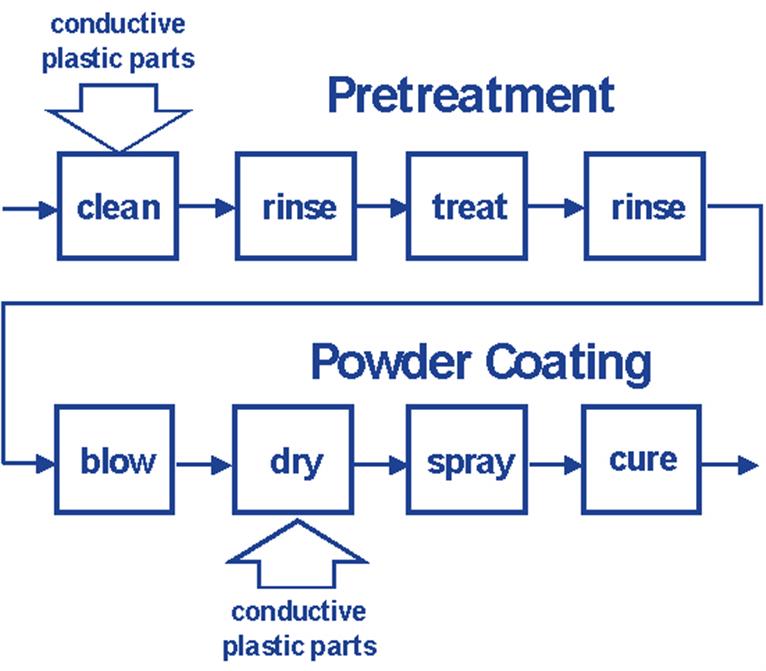

Powder Coat vs. Paint While powder layer and paint are very comparable, they both stand out at finishing different products because of their unique structures. Paint is a much more cost effective service that is easier to color suit, but it likewise consists of solvents that make it harmful to shop and also can damage the setting.Powder layer on stainless steel a naturally sturdy product treasured for similar features yields components that can stand up to even the harshest environments. Preparing for the Powder Finish Process Much like paint, powder covering calls for a thorough prep work of all elements in order to guarantee the coating adheres correctly.

What Does Powder Coating In Santa Clarita Mean?

The sort of application used is figured out by the distinct demands of the components being covered, with the substratum's heat resistance generally being the determining factor. In an electrostatic deposition, the finishing is applied using an electrostatic spray deposition in a powder spray cubicle. The fluidized powder material is after that distributed from a feeder to a spray weapon that gives the powder with an electric charge (santa clarita powder coating shop).Once the layer of powder is in place, the parts are sent to be about his treated. The fluidized bed powder covering approach works by preheating components and also browse around these guys dipping them into powdered material inside a fluidized bed.

The 15-Second Trick For Powder Coating In Santa Clarita

Healing Process The healing process varies between electrostatic deposition as well as fluidized bed powder finish approaches. For electrostatic deposition, parts are treated in a powder treating stove that is commonly run at in between 325 and 450 levels Fahrenheit. Relying on the size as well as form of the components, the cure time will vary anywhere from 10 mins to a hr.To cure fluidized bed coated components, the parts can be covered prior to or after being passed with the powder finish cloud. In the first approach, the parts do not call for added treating, as use this link well as in the second approach, the part is treated in a stove comparable to that utilized during the electrostatic deposition process.

The Single Strategy To Use For Powder Coating Santa Clarita

We've spent even more than 40 years developing our powder covering approaches and have the know-how required to use these coatings to everything from food manufacturing devices to medical tools as well as furnishings. We additionally supply resilient corrosion- and also heat-resistant powder finishing services.Metal components can be do with either powder layer or wet paint. While they serve a similar feature, each layer type has a distinct collection of advantages and also disadvantages. Both coverings include materials, ingredients, and pigments. The significant distinction is solvent: wet paint includes solvent, however powder layer does not. The solvent in damp paint maintains all the various other parts in suspended fluid type.

Some Known Facts About Powder Coat Santa Clarita.

Report this wiki page